Contrary to common belief, forklift technology actually dates back over a hundred years. With many of us believing that these convenient machines are a relatively new invention, it turns out that they go all the way back to the industrial revolution and forktruck technology continues to be developed to this day in a bid to make them as sustainable and as eco-friendly as possible. But how did the idea for a forklift truck come about and where is the technology headed?

When was the forklift invented?

The industrial revolution saw a considerable increase in machinery throughout many sectors, including agriculture, construction and manufacturing. In order to make it easier for manual workers, and to relieve many animals of hard, physical work, a lifting truck was invented. Developed in 1887, the lifting truck was manufactured and brought into mainstream production in order to, as the name would suggest, lift and transport large, heavy goods with ease.

With the lifting truck working so effectively across a number of industries, the progression of the machine stagnated for at least two decades. Although, in 1906, the first powered loading truck was invented when a railroad worker attached a battery to a baggage cart. As this was seen to be more efficient and modern than the 1887 lifting truck, the powered loading truck quickly replaced its older counterpart as it grew to be more favourable among manual labour workers.

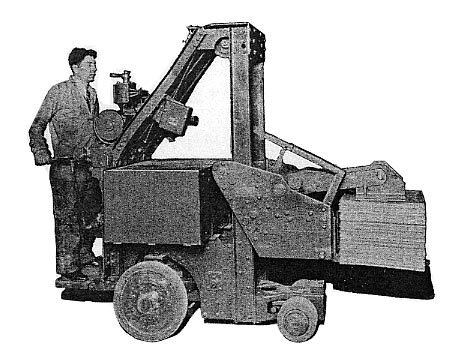

This paved the way for the first steel trucks, somewhat resembling the forklifts we know today. However, its lifting platform consisted of a sheet of solid metal as opposed to the modern forks that eventually replaced it.

What role did forklifts play during WW1 and WW2?

Some of the earliest forklift models were used during the World War One war effort, globally. As many of the countries’ men enlisted in the army during this time, they were left with very few manual labour workers who, ordinarily, would have done the job that a forklift does by hand. As workforces dwindled, many businesses needed a quick and efficient replacement to pick up the slack and this came in the form of a forklift truck.

By 1915, a powered steel lift truck was invented and produced in Ipswich, England. This allowed loads to be lifted both horizontally and vertically for the very first time. Due to its new capabilities, demand for the machine grew and so the manufacturers spent the inter-war years developing the machine. Eventually, they had replaced the solid metal platform for the conventional forks that are still used now. Hydraulic power was then added to the lifting element, making it even more efficient and effective when lifting large or heavy loads.

Due to its brand new, modern developments, forklifts proved to be very popular during World War Two, quickly becoming a vital piece of machinery. It meant that food, ammunition and other war supplies could be lifted and transported efficiently and swiftly. However, at this time, forklifts still didn’t have a roof, so they weren’t as safe for operators as they could have been.

How did forklifts develop during the 1950’s and 1960’s?

After the war, forklifts boomed in popularity and quickly became a much sought-after piece of material handling machinery. As forklift trucks grew in demand among warehouse owners and early distribution centres, manufacturers had to go back to the drawing board in order to sell more models.

The forklifts used during both wars were much too large and cumbersome for commercial, as opposed to industrial, use. There were a number of factors that needed to be worked on before the forklift went onto the mainstream market, including:

- Maneuverability – early forklifts were very large and rather heavy, which made them difficult to operate, especially in narrow spaces

- Lifting heights – they could only lift loads to a relatively short height, making storage and space-saving efforts more challenging

- Emissions – the first forklifts weren’t suitable for use indoors, despite being used inside anyway which subsequently caused some health problems

- Safety – the forklift still didn’t a roof, making it more dangerous for operators

- Operator comfort – forklift drivers only had a small pedestal seat to sit on which wasn’t a very comfortable feature in early forklift models.

By the 1960’s, in order to sell more forklifts for everyday warehouse and distributor use, their design was revised and eventually resulted in a roof being added. Backrests were also introduced for driver comfortability, together with a few more safety features for the peace of mind of employers and their workers.

How did forklifts develop into what they are today?

Forklifts went through considerable changes during the 1980’s, with operator comfort being at the forefront of the designers’ minds. They soon became more ergonomic, ensuring that less injuries were sustained over a long period of time as a result of bad posture, for example. This meant that fewer workers were taking time off sick and efficiency and productivity soon improved as a result.

Today, forklifts are manufactured and developed with the environment in mind. With exhaust emissions standards now playing a vital role in the production of forklifts worldwide, forklifts are more eco-friendly than ever before, particularly if you opt for an electric or LP Gas alternative.

Fuel cell technology is now being looked at when it comes to forklift manufacturing. As the industry is now worth approximately £17 billion, it’s no wonder that innovative, modern designs and technology are now at the forefront of forklift design and production, helping to sustain, and potentially grow, that figure.

Here’s how Hire Forklifts can help you today

Hire Forklifts are able to provide customers throughout the East Midlands and the surrounding areas with high-quality material handling equipment, all made to the highest possible standards for your peace of mind. As well as being able to rent diesel, electric, LP Gas, articulated and multidirectional forklifts from us, you’ll also be able to hire numerous other warehouse machines, including:

- Reach trucks

- Pallet trucks

- Order pickers

- Teletruks

- Stackers

- Scissor lifts

- Cherry pickers

Not only do we have a wide range of material handling equipment available for you to choose from, but you’ll also be able to pick a manufacturer that’s right for you and your needs. Whether you’ve only ever worked with machines constructed by Mitsubishi or prefer the comfortability of another brand, we’ll have several options for you. As well as Mitsubishi, the other makes and models we’re able to provide include:

- Aisle-Master

- Bendi

- Caterpillar

- CombiLift

- Heli

- Hyster

- JCB

- Linde

- Toyota

No matter what it is you need, whether you require long or short term hire, we’ll have a variety of options available to suit your warehouse operations, no matter how busy things may get. Whether you need an individual machine or an entire fleet to help get the job done, you’ll always be able to look to us here at Hire Forklifts to supply you with robust, reliable, and above all, safe material handling equipment every single time.

For more information about how our team of specialists will be able to help you today, get in touch with us at a time to suit you – our knowledgeable experts will be able to talk you through your options and set the wheels in motion for a convenient, reputable and transparent rental experience that you can always rely on.